Seawater Electro-chlorination System (chlorination system)

Seawater Electro-chlorination System (chlorination system)

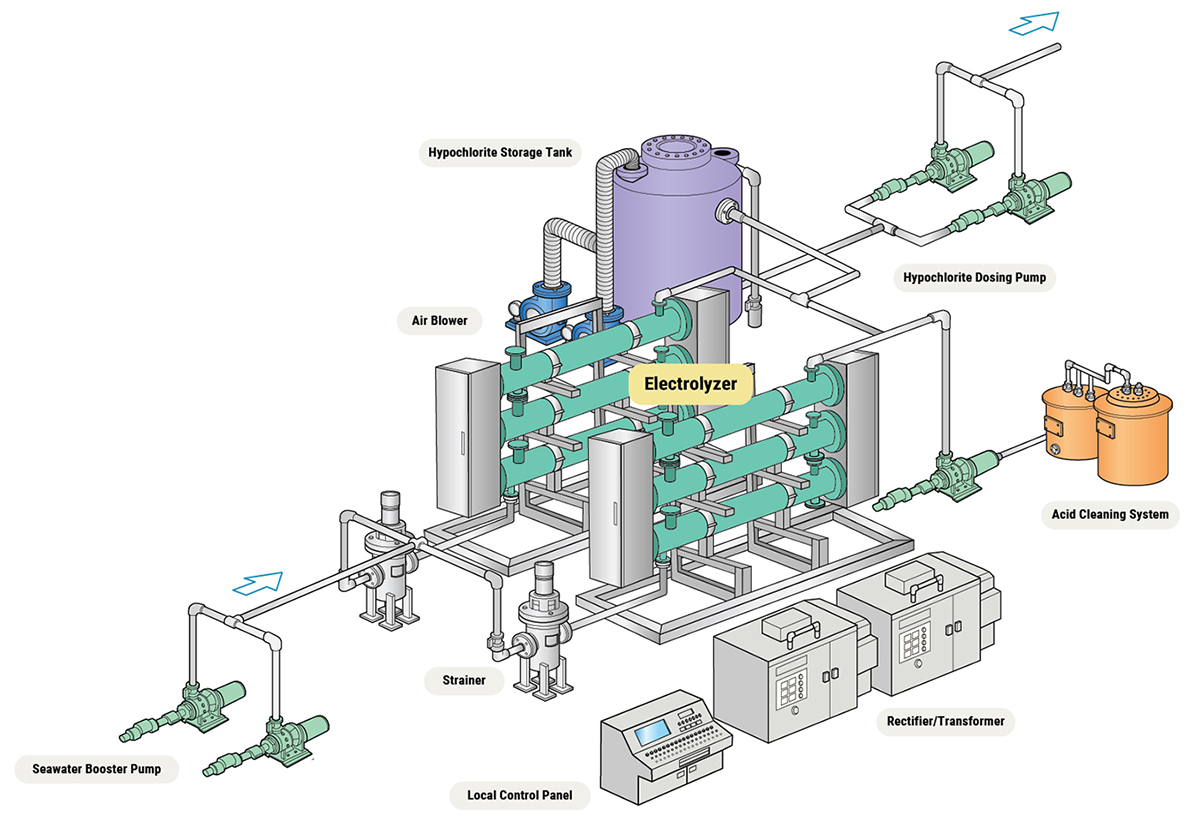

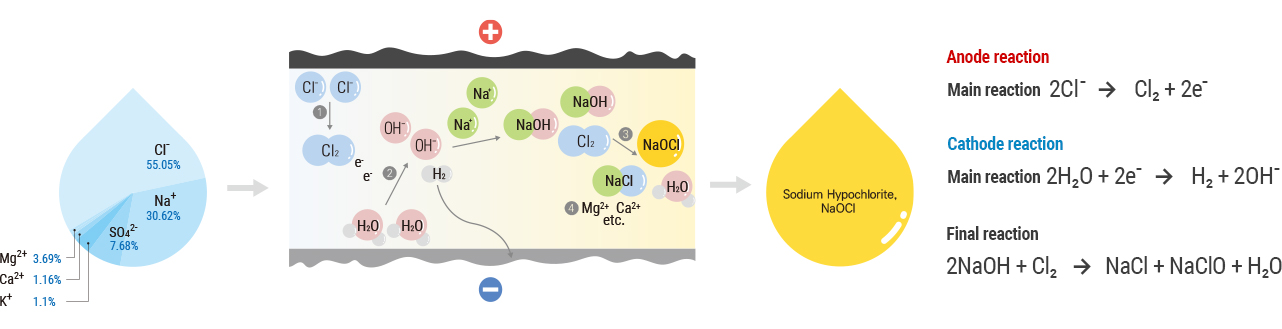

Seawater Electro-chlorination System directly electrolyzes seawater and generates sodium hypochlorite with the use of NaCl, an element in seawater. By injecting the generated sodium hypochlorite into the seawater intake of a power plant or LNG terminal, it is possible to inhibit any attachment and growth of sea creatures, such as shell and seaweed, into a cooling system, and thereby to prevent poor heat exchange efficiency (e.g., increase in resistance of fluid conduit, reduction in heat transfer coefficient) and corrosion caused by pipe clogging. The concentration of the generated sodium hypochlorite is 1,000 ~ 2,000ppm, and the concentration in the intake is 2 ~ 4ppm.

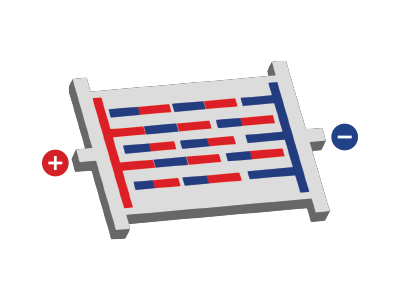

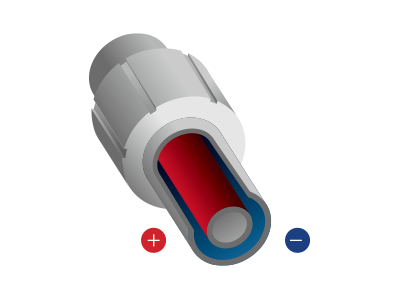

Types

| Mono-poiar Type | Bi-polar Type | Tubuiar / Multi Tubular Type |

|---|---|---|

|

|

|

|

|

|

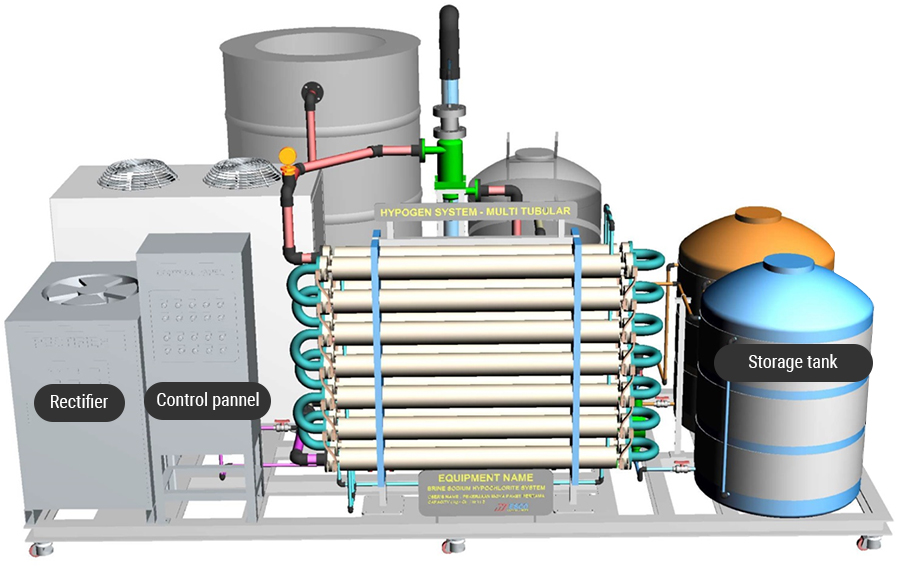

HYPOGEN® SYSTEM

| Electrolyzer Model | Max. Capacity |

Output Concentration |

Seawater Flowrate |

DC Amperage Max. |

DC Voltage Max. |

|

|---|---|---|---|---|---|---|

| Type | Module | kg·Cl2/hr | ppm | ㎥/hr | A | V |

| Mono-polar Type |

WNM-1012 | 12 | 240 | 50 | 13,000 | 6 |

| WNM-6030 | 30 | 1,500 | 20 | 5,500 | 36 | |

| WNP-6060 | 60 | 1,500 | 40 | 11,500 | 36 | |

| WNM-8040 | 40 | 1,500 | 27 | 5,500 | 48 | |

| WNP-8060 | 60 | 1,500 | 40 | 7,200 | 48 | |

| Bi-polar Type | WBH-4022 | 22 | 1,500 | 15 | 1,000 | 144 |

| WBH-3050 | 50 | 1,500 | 32 | 1,800 | 180 | |

| WBH-4080 | 80 | 1,500 | 53 | 2,000 | 150 | |

| WBV-2045 | 45 | 1,500 | 100 | 11,000 | 150 | |

| Multi Tubular / Tubular Type |

WMT-1220 | 20 | 1,500 | 13 | 1,000 | 144 |

| WNT-1010 | 10 | 1,500 | 7 | 1,300 | 60 | |

*Aside from the above models, customized models can be made and supplied in line with a customer’s operation environment and requirements.

A list of main achievements

BWTS

BWTS is the technology of removing or sterilizing underwater organisms and microorganisms in ballast water,

blocking any flow of foreign species from other areas.

It is divided into ‘pipe treatment type’ and ‘tank treatment type’.

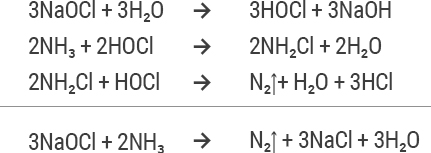

The pipe treatment type approach is used to make treatment at the time when sea water flows in and out of ship. The tank treatment type approach is used to make treatment at sea after injection. Mostly, the pipe treatment type is adopted. Sterilization is made physically or chemically. As physical methods, there are UV irradiation, heating, and ultrasound. For chemical sterilization, chlorine, chlorine dioxide, ozone, hydrogen peroxide, and other organic chemicals are used. In particular, the ballast water treatment approach using electrolysis is used to electrolyze sea water and generate electrolyzed water (generally, hypochlorous acid water, HOCL: sterilization of various bacteria and viruses), and then mix the generated electrolyzed water with the ballast water flowing from sea to a ballast tank so as to sterilize the ballast water.

Chlorine components remain in water for a certain time, inhibiting the generation of microorganisms. As salt water is electrolyzed, it is possible to generate hypochlorous acid ions (OCl⁻),

oxygenerated water (H2O2), and others.

In 2004, the International Maritime Organization (IMO) adopted International Convention for the Control and Management of Ships` Ballast Water and Sediments.

It is mandatory to install “IMO D-2” in the new ships having been built since 2012 and in all the ships having been operated since 2017.